The pharmaceutical industry, verifiably administered by rigid directions and systematic bunch fabricating, is right now experiencing a radical change fueled by progressed apparatus and digitalization. This move, frequently named Pharma 4.0, guarantees to quicken medicate advancement, slice generation costs, and clear the way for genuine personalized medication. The center of this transformation lies in ten interconnected, cutting-edge advances that are reclassifying what a medicate plant looks like.

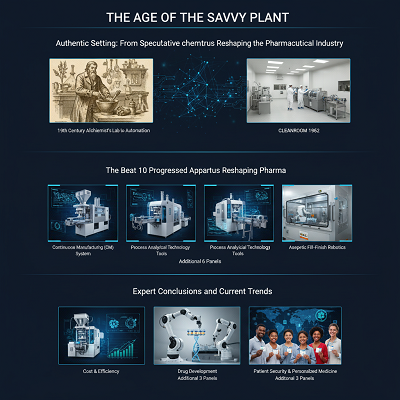

🏛️ Authentic Setting: From Speculative chemistry to Automation

The present day pharmaceutical industry developed in the mid-19th century, advancing from pharmacists and chemical color companies. Early fabricating was characterized by labor-intensive, small-batch forms. The advancement of significant drugs like penicillin in the mid-20th century impelled a thrust for mass generation, driving to the far reaching appropriation of large-scale apparatus like high-speed tablet presses, capsule filling machines, and fundamental rankle bundling lines.

A noteworthy turning point was the presentation of the cleanroom concept in 1962, a foundational step toward sterile fabricating. For decades, the industry depended on successive, discrete group preparing. This strategy, whereas vigorous for quality control, is inalienably moderate, capital-intensive, and regularly unbendable, driving to long lead times and tall fabric squander. The require for more prominent productivity, lower costs, and improved quality control got to be the driving drive behind the current thrust for progressed automation.

🤖 The Beat 10 Progressed Apparatus Reshaping Pharma

Today’s pharmaceutical fabricating is moving from straightforward computerization to profound integration of advanced and physical innovations. Here are the best 10 progressed apparatus and advances driving the charge:

1. Ceaseless Fabricating (CM) Systems

- Unlike bunch handling, CM coordinating all steps—from crude fabric input to last dose form—into a single, continuous generation line.

- Apparatus: Exceedingly coordinates frameworks of powder feeders, twin-screw granulators, tablet presses, and coaters.

- Affect: Definitely diminishes generation time (weeks to hours), minimizes office impression, and progresses item quality consistency.

2. Prepare Expository Innovation (PAT) Tools

These are modern, real-time checking and control frameworks coordinates into the fabricating line.

- Apparatus: Near-Infrared (NIR) and Raman spectrometers, stream cytometers, and progressed sensor technology.

- Affect: Empowers “quality by plan” (QbD) by permitting immediate alterations, guaranteeing item quality is built-in or maybe than tried for afterward.

3. High-Throughput Screening (HTS) Robots

Used intensely in sedate disclosure, these automated frameworks robotize the prepare of testing millions of compounds for natural activity.

- Apparatus: Multi-axis automated arms, microplate perusers, fluid taking care of frameworks, and computerized incubators.

- Affect: Exponentially quickens the early arrange of medicate revelation, finding potential sedate candidates speedier and more cost-effectively.

4. Aseptic Fill-Finish Robotics

These specialized automated cells handle the touchy, sterile filling of injectable sedate items (vials, syringes) with negligible to zero human intervention.

- Apparatus: Isolator innovation, glove-free mechanical arms, and progressed serialization printers.

- Affect: Essentially brings down the chance of defilement in sterile items, progressing persistent security and administrative compliance.

5. Progressed Bioreactors and Fermenters

Essential for creating biologics (antibodies, antibodies), present day frameworks offer exceedingly controlled, single-use environments.

- Apparatus: Single-use (expendable) bioreactors, persistent chromatography frameworks, and ultrafiltration units.

- Affect: Increments adaptability, diminishes cleaning approval time between clusters, and speeds up the generation of complex biologics.

6. 3D Printing (Added substance Manufacturing)

While still developing, this innovation permits for the printing of strong measurement shapes (pills).

- Apparatus: Specialized industrial-grade powder bed combination or folio flying printers.

- Affect: The extreme device for personalized medication, empowering on-demand creation of drugs with custom measurements and discharge profiles.

7. Computerized Visual Review Frameworks (AI-Driven)

These supplant human eyes in checking last items for surrenders like breaks, outside particles, or erroneous packaging.

- Apparatus: High-resolution cameras, machine vision computer program, and AI/Machine Learning algorithms.

- Affect: Gives immaculate, objective, high-speed quality control, driving to predominant item security and integrity.

8. Advanced Twin Technology

This is not physical apparatus but a virtual reproduction of the whole fabricating prepare, made utilizing sensor data.

- Apparatus: High-performance computing frameworks, mechanical IoT (IIoT) sensors, and reenactment software.

- Affect: Permits engineers to recreate changes, anticipate hardware disappointment (prescient upkeep), and optimize forms without disturbing genuine production.

9. Blockchain-Enabled Serialization and Track-and-Trace Systems

These frameworks track person sedate bundles from the production line floor to the patient.

- Apparatus: High-speed 2D code printers, vision frameworks, and specialized conglomeration stations associated to a secure, decentralized computerized ledger.

- Affect: Combats falsifying, upgrades supply chain straightforwardness, and guarantees compliance with worldwide traceability commands (e.g., U.S. DSCSA, EU FMD).

10. Increased Reality (AR) & Virtual Reality (VR) Preparing and Upkeep Tools

While essentially program, these advances interface straightforwardly with and direct human administrators on the fabricating floor.

- Apparatus: Savvy glasses (AR headsets), specialized tablets, and VR simulators.

- Affect: Definitely diminishes blunder rates in complex gear operation, encourages quick preparing, and empowers inaccessible master direction for support and repair.

🗣️ Master Conclusions and Current Trends

The agreement among industry pioneers is that the future of pharma fabricating is completely digitized, spry, and patient-centric.

Current Trends:

- Integration of AI/ML: Counterfeit Insights (AI) and Machine Learning (ML) are the ‘brains’ behind this unused apparatus, utilizing Enormous Information from PAT instruments to ceaselessly self-optimize generation parameters, decreasing the require for human intervention.

- Move to Biologics: The rise of complex organic drugs requests more advanced, exceedingly controlled fabricating gear, driving the selection of single-use and persistent bioprocessing technologies.

- Cybersecurity Center: As operations ended up hyper-connected (IIoT), apparatus must be built with vigorous cybersecurity conventions to secure delicate mental property and avoid disruption.

Experts broadly concur that the administrative framework—long a obstruction to receiving unused technologies—is at long last advancing. The FDA and other worldwide bodies are effectively empowering and making direction for Ceaseless Fabricating, recognizing its potential to convey higher, more reliable quality drugs. The challenge presently lies not fair in innovation, but in upskilling the workforce to oversee and keep up these complex, data-driven systems.

📈 Suggestions for the Industry and Open Health

The selection of this progressed apparatus carries significant suggestions for all stakeholders.

Cost and Efficiency

Advanced apparatus, in spite of tall introductory venture, leads to critical long-term taken a toll decreases. Persistent fabricating requires less floor space, devours less vitality, and significantly cuts squander. The exactness and quality control advertised by AI-driven assessment and PAT frameworks decrease the frequency of expensive clump disappointments. This productivity pick up can eventually decipher to lower medicate generation costs.

Drug Development

Robotic HTS and AI-guided detailing improvement are quickening time-to-market. By optimizing the fabricating handle amid improvement (QbD), companies can record more vigorous administrative entries and maintain a strategic distance from long post-approval changes. This permits unused drugs to reach patients faster.

Patient Security and Personalized Medicine

The greatest advantage is in upgraded security and quality. Robotized, closed frameworks minimize human blunder and defilement chance. Moreover, the combination of 3D printing and adaptable, small-scale secluded fabricating opens the entryway for accuracy wellbeing, permitting for the temperate generation of individualized or small-batch solutions for specialty persistent populaces. The capacity to track drugs through serialization too gives a significant defense against the worldwide danger of fake pharmaceuticals.

In conclusion, the advanced apparatus of Pharma 4.0 is not just an incremental overhaul; it is a worldview move. By combining mechanical accuracy with advanced insights, the industry is moving toward a future where drugs are created speedier, cheaper, more dependably, and custom-made to the interesting needs of each patient.