Hot-Melt Expulsion (HME), a foundational prepare over the plastic, nourishment, and pharmaceutical businesses, is experiencing a significant change. The computerized insurgency known as Industry 4.0 is joining HME into a cohesive “keen fabricating” environment, promising phenomenal picks up in productivity, quality, and handle nimbleness. This joining marks a critical jump from conventional handle control to independent, data-driven production.

Background and Chronicled Context

From Elastic to Pharmaceuticals

The concept of expulsion, constraining a fabric through a formed kick the bucket, has roots dating back to the late 18th century, but Hot-Melt Expulsion as a advanced preparing innovation was built up in the 1930s. At first, it quickly got to be crucial in the plastics, elastic, and nourishment businesses for making items like channels, movies, and different nourishment structures.

HME’s passage into the pharmaceutical industry in the 1970s demonstrated to be a major turning point. It advertised a solvent-free, ceaseless prepare for fabricating strong measurement shapes, most strikingly for making Undefined Strong Scatterings (ASDs). ASDs are vital for upgrading the bioavailability and solvency of ineffectively water-soluble Dynamic Pharmaceutical Fixings (APIs). The move from conventional bunch preparing to ceaseless HME adjusts impeccably with the current administrative thrust by bodies like the FDA for Persistent Fabricating (CM) and the standards of Quality by Plan (QbD). This built up a establishment of quality-focused, in-line estimation that would afterward empower the full execution of keen manufacturing.

Current Patterns: The Center of Shrewd HME

The integration of Industry 4.0 advances is making a “keen HME” environment characterized by real-time information and interconnectivity.

The Part of Handle Explanatory Innovation (PAT) and Huge Data

The greatest current drift is the more profound integration of Handle Explanatory Innovation (PAT) devices, but presently increased by Enormous Information analytics and Machine Learning (ML).

- Real-Time Quality Control: PAT instruments like Near-Infrared (NIR) and Raman spectroscopy are mounted straightforwardly onto the extruder, giving moment, non-destructive investigation of the melt’s Basic Quality Qualities (CQAs), such as sedate substance and strong scattering status.

- Predictive Modeling: The deluge of information collected from PAT sensors, along with basic handle parameters (CPPs) like screw speed, temperature, torque, and bolster rate, is nourished into ML calculations. These models learn the complex, non-linear connections between input factors and last item quality, permitting for prescient and prescriptive analytics. This implies the framework can foresee a quality deviation some time recently it happens and indeed endorse parameter alterations to keep up a idealize CQA.

- Digital Twins: Progressed producers are building Computerized Twins—virtual copies of their HME handle. These models permit engineers to reenact changes in definition or preparing conditions without disturbing the physical line, quickening investigate and improvement (R&D) and encouraging speedy scale-up.

Automation and Flexibility

Smart HME empowers more noteworthy robotization and item adaptability, a key request of the cutting edge market.

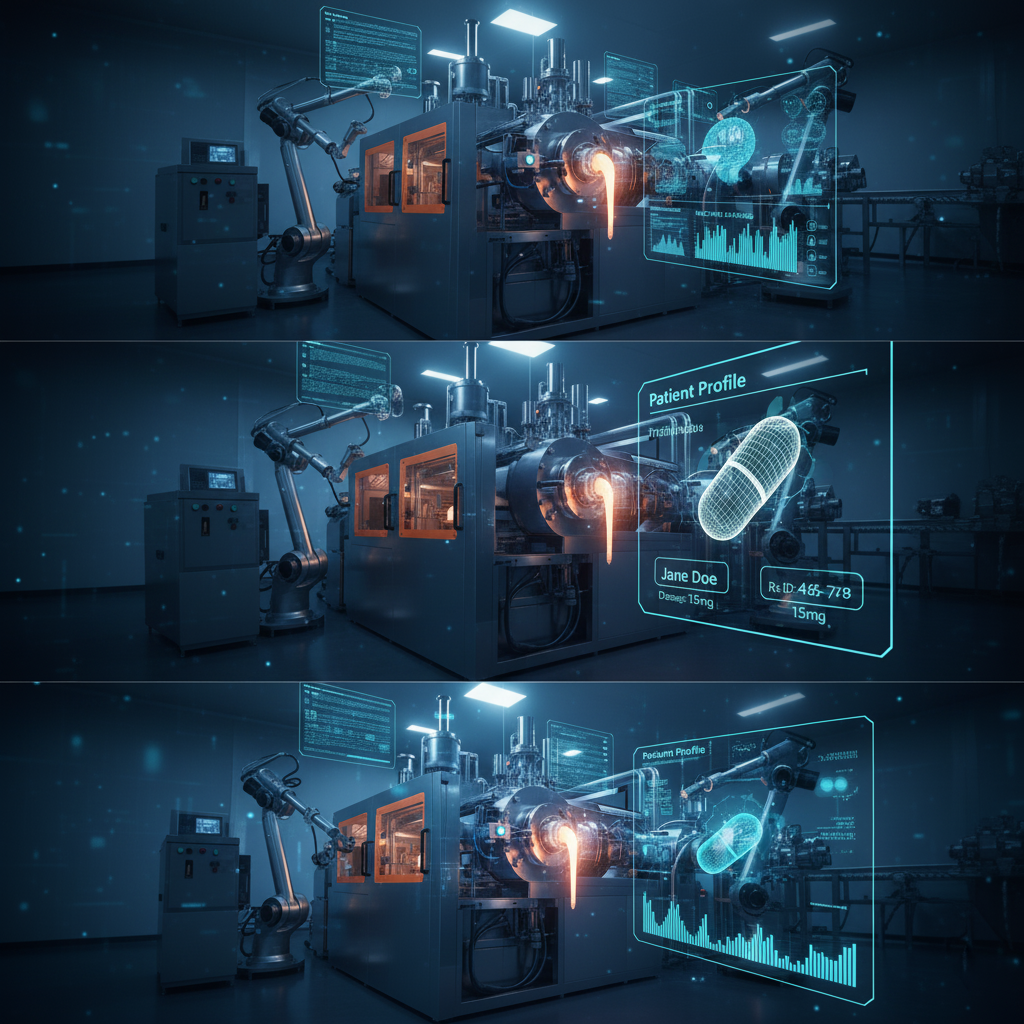

- Self-Optimizing Frameworks: The combination of ML and progressed mechanization permits the HME line to be self-optimizing. If an outside unsettling influence (like a slight variety in crude fabric) happens, the framework consequently alters parameters like screw speed or barrel temperature in milliseconds, keeping up a reliable item quality—a concept known as Closed-Loop Control.

- Personalized Pharmaceutical and 3D Printing: Shrewd HME lines are being utilized to make fibers for 3D Printing of measurement shapes. This is a pivotal step towards personalized pharmaceutical, permitting for the on-demand generation of tablets with customized doses or geometries.

Expert Conclusions: Quality, Proficiency, and Cost

Experts generally concur that keen fabricating is no longer an discretionary overhaul but a competitive need for HME clients, especially in the profoundly directed pharmaceutical sector.

“The genuine esteem of Industry 4.0 in HME is the move from ‘detect and discard’ to ‘predict and prevent’,” states a driving pharmaceutical fabricating specialist. “By ceaselessly approving quality in real-time, the require for broad post-process quality checks is radically diminished, empowering real-time item release.”

The benefits decipher specifically to the foot line:

- Improved Productivity: Nonstop optimization driven by AI decreases fabric squander, brings down vitality utilization, and minimizes impromptu downtime through Prescient Upkeep. Sensors always screen machine wellbeing (vibration, temperature, control draw) to hail potential disappointments well some time recently a breakdown happens, permitting upkeep to be planned proactively.

- Improved Quality: The atomic level of blending accomplished in HME, coupled with the tight, self-adjusting prepare control of Industry 4.0, comes about in exceptional substance consistency and item reproducibility.

- Lower Working Costs: The tall degree of mechanization and the capacity to run 24/7 without steady administrator intercession drives noteworthy decreases in operational use (OpEx).

Suggestions and The Future

The full realization of keen HME is set to rethink nonstop fabricating and supply chains.

Regulatory and Compliance Shifts

The move to data-rich, savvy frameworks offers a unused worldview for administrative compliance. Instep of basically recording that quality checks were performed, producers can give a persistent information stream, demonstrating that the item was fabricated beneath control at all times. This underpins the extreme objective of Real-Time Discharge Testing (RTRT), dispensing with the time-consuming isolate and testing periods truly required for group release.

Supply Chain Agility

Connected keen HME lines encourage Even and Vertical Integration.

- Even: Expulsion information can be connected over numerous generation locales, guaranteeing worldwide consistency.

- Vertical: Generation information can be right away shared with Venture Asset Arranging (ERP) frameworks, permitting for programmed alterations to stock, planning, and coordinations in reaction to real-time yield. This makes a profoundly dexterous and responsive supply chain competent of responding immediately to request fluctuations.

Challenges Ahead

The appropriation way is not without obstacles. The beginning capital speculation for progressed sensors, high-performance computing, and cybersecurity foundation is significant. Moreover, there is a basic require for a unused, digitally-skilled workforce—engineers and administrators who can oversee and decipher the complex yields of machine learning models or maybe than basically turning dials. Cybersecurity is too fundamental, as completely associated, independent industrial facilities display modern vulnerabilities that must be thoroughly protected.

In conclusion, Industry 4.0 is changing Hot-Melt Expulsion from a dependable handle into an brilliantly, self-aware fabricating unit. By leveraging the control of information, it is not fair moving forward quality and effectiveness; it is setting up a modern standard for speed, nimbleness, and exactness in high-value fabricating segments over the globe.