Hot break down ejection (HME), a plan long utilized in the plastics and food businesses, has found a cutting edge reason in pharmaceutical manufacturing, promoting a solvent-free methodology for making advanced cure transport systems. By and by, the HME scene is encountering a critical alter, driven by the guidelines of Industry 4.0, or the fourth mechanical change. This assembly of physical shapes with computerized development is making “sharp” fabricating plants where capability and quality are no longer reasonable goals, but an natural work of the system.

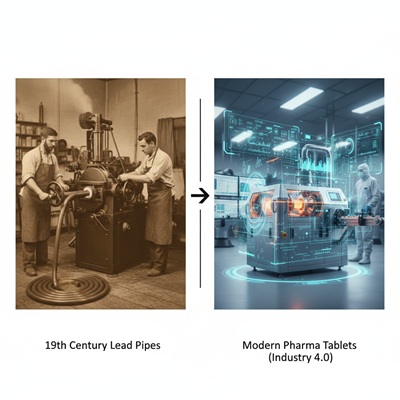

A See Back: From Plastic Channels to Pharma Tablets

The roots of hot relax removal take after back to the late 18th century, when it was utilized to provide lead channels. By the 1930s, the advancement had progressed and was broadly grasped by the plastics industry for taking care of thermoplastic materials. Its travel into the pharmaceutical space begun in the 1970s, where it publicized a critical advantage: the capacity to handle energetic pharmaceutical fixings (APIs) and polymers without the utilize of solvents. This “green strategy” illustrated instrumental in taking care of a major challenge for calm developers—improving the dissolvability and bioavailability of incapably dissolvable drugs.

Early HME systems were modestly clear, depending on manual modifications and batch-based shapes. The introduction of single-screw extruders and, a while later, more present day twin-screw extruders advanced mixing and efficiency. In any case, these systems still required the real-time feedback and interconnection that would characterize the taking after period of manufacturing.

The Progressed Move: Industry 4.0’s Center Technologies

Industry 4.0 is not a single advancement but a suite of interconnected computerized devices that make a cyber-physical system. In the setting of HME, these progresses work in concert to build a more sagaciously and responsive manufacturing environment:

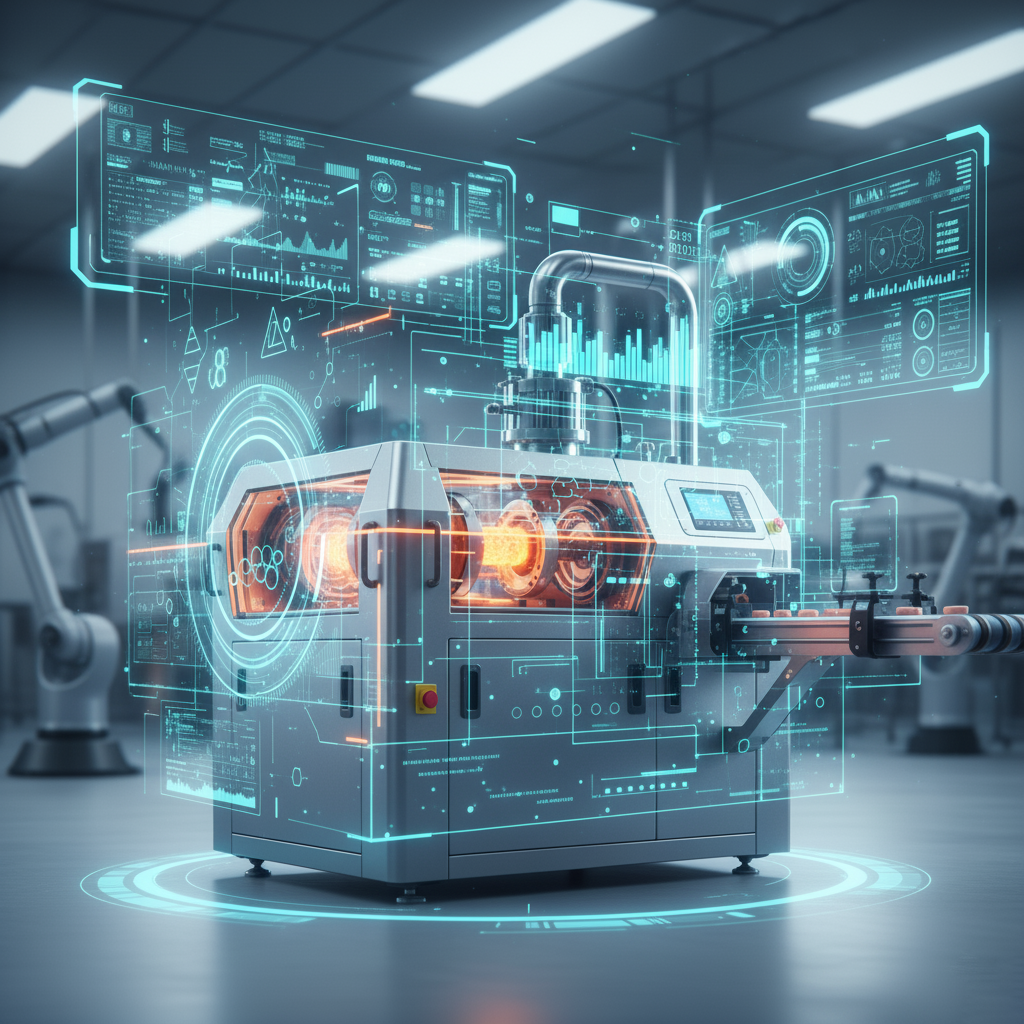

- Internet of Things (IoT): Sensors and sharp contraptions are embedded all through the HME handle, collecting colossal wholes of data in honest to goodness time. These sensors can screen everything from temperature and weight interior the barrel to screw speed, motor torque, and undoubtedly the properties of the extrudate itself.

- Big Data Analytics and AI: The data collected by IoT sensors is analyzed by able machine learning calculations. These calculations can recognize designs, recognize quirks, and predict potential equip disillusionments a few time as of late they happen. This is the foundation of prescient back, which minimizes downtime and lessens costs.

- Cloud and Edge Computing: Data from the generation line floor is arranged either in the cloud or at the “edge,” close to the source. Edge computing is particularly vital for HME, as it licenses for near-instantaneous decision-making, such as changing handle parameters in real-time to alter a quality issue.

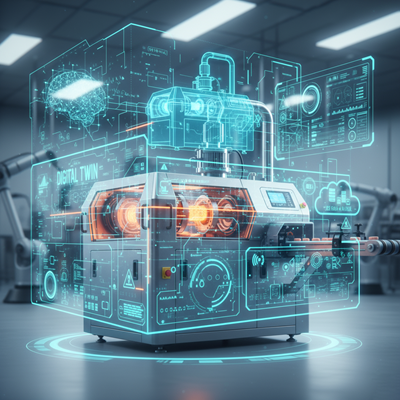

- Digital Twins: This is a virtual duplicate of the physical HME get ready, a enthusiastic entertainment that gives a high-fidelity illustrate of the system. It licenses engineers to test present day definitions, optimize parameters, and get ready staff in a risk-free environment, through and through reducing the time and taken a toll of development.

Current Designs and Ace Opinions

The integration of Industry 4.0 into HME is moving past speculation and into sharpen. Pharmaceutical companies and equipment makers are getting a handle on these advancements to finish higher levels of Handle Illustrative Development (PAT) and Quality by Arrange (QbD), two key regulatory frameworks that energize a proactive approach to quality.

Experts agree that sharp manufacturing is a game-changer for the HME promote. The capacity to screen and control essential get ready parameters in real-time ensures more vital thing consistency and reduces the risk of batch-to-batch changeability. Dr. Jane Carter, a driving master in pharmaceutical creating, notes, “The honest to goodness control of Industry 4.0 is its capacity to make a self-regulating system. Instep of reacting to issues, the HME plan can anticipate and alter them on its have, driving to a basic reducing in waste and a higher quality product.”

Another key incline is the move toward diligent manufacturing. Genuinely, calm era has been a batch-based get ready, which is frequently time-consuming and slanted to abnormalities. HME, with its nonstop stream, is a ordinary fit for this illustrate. The development of sharp progresses makes ceaseless creating undoubtedly more overwhelming, allowing for steady, end-to-end era with unimportant human intervention.

Implications and the Road Ahead

The distant coming to assignment of Industry 4.0 in HME has far-reaching proposals for the entirety pharmaceutical regard chain.

- Enhanced Efficiency and Taken a toll Reducing: By minimizing downtime, reducing misuse, and optimizing resource task, sharp HME systems lead to basic taken a toll speculation reserves. The capacity to make personalized pharmaceutical in smaller, more compelling clumps in addition opens up unused exchange models.

- Improved Quality and Security: Real-time quality control and the reducing of human botch lead to more secure, more dependable cure things. This is especially fundamental for a significantly coordinated industry like pharmaceuticals.

- More unmistakable Flexibility and Mass Customization: Canny HME licenses for fast changeovers between definitions and the era of a distinctive run of estimation shapes, from tablets and capsules to embeds and 3D-printed drugs. This flexibility is principal for gathering the creating ask for personalized medicine.

- Workforce Progression: The move to sharp manufacturing requires advanced aptitudes. The industry will require less manual directors and more data analysts, control system engineers, and cybersecurity masters to manage these complex, interconnected systems. Companies will require to contribute in planning and upskilling their workforce to keep pace with the mechanical revolution.

While the early on wander can be tall and cybersecurity remains a concern, the long-term benefits of joining Industry 4.0 into hot break up ejection are irrefutable. As the advancement gets to be more open and versatile, it will continue to reshape the pharmaceutical industry, clearing the way for a unused period of more brilliant, more viable, and more reliable calm fabricating.