For decades, the worldwide economy has run on a straightforward preface: greater is more secure. Supply chains worked by stockpiling colossal inventories, a methodology that advertised a buffer against erratic request but came at a stunning cost—financially and, progressively, naturally. Nowadays, in any case, a Japanese-born logic is being re-evaluated not fair for its cost-cutting ability, but as a basic apparatus for building a greener future: Just-in-Time (JIT) Manufacturing.

JIT, a center column of Incline Fabricating, requests that materials and components arrive at the generation line as it were precisely when they are required. By disposing of the endless inventories that characterize conventional supply chains, JIT intrinsically handles one of the greatest sources of corporate squander, making a compelling case for its part in making genuinely maintainable operations.

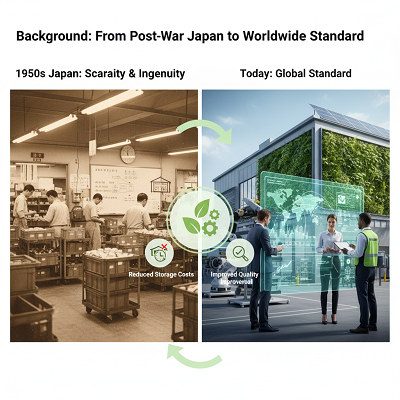

Background: From Post-War Japan to Worldwide Standard

The roots of JIT are indistinguishable from the challenges confronted by post-World War II Japan. Not at all like the resource-rich Joined together States, Japan had constrained arrive, capital, and crude materials. This shortage impelled a drive for greatest effectiveness and least squander, which was formalized into the Toyota Generation Framework (TPS) by build Taiichi Ohno in the 1950s and 60s.

Ohno’s center logic was the tenacious end of “Muda” (squander), which he categorized into seven sorts, counting overproduction, holding up, and abundance stock. The straightforward act of dispensing with tremendous stockpiles meant:

- Diminished Capacity Costs: No require for expansive, energy-intensive warehouses.

- Less Out of date quality: Items and parts wouldn’t sit around to ended up obsolete or spoiled.

- Made strides Quality Control: Littler generation bunches made abandons simpler to spot and follow back to the source quickly.

While at first driven by financial need, the inborn squander lessening of JIT has since demonstrated to be a outline for natural stewardship.

JIT’s Commitment to Natural Sustainability

JIT’s center on proficiency and squander end offers significant, coordinate benefits for the environment, straightforwardly supporting the thrust for a circular economy.

Waste Minimization

The most critical natural affect comes from the rule of creating as it were what is required, when it is needed.

- Diminished Overproduction: This cuts down on the fabricating resources—raw materials, vitality, and water—that would something else be used on items that may conclusion up in a landfill.

- Less Deterioration and Out of date quality: Particularly basic in businesses like pharmaceuticals (clinical trial materials) and food/beverages, JIT significantly diminishes the sum of item that must be arranged of due to expiry or a plan change.

Energy and Asset Optimization

By lessening the physical impression of the operation, JIT spares vitality utilized for warming, cooling, and lighting endless capacity offices. Moreover, a highly-tuned JIT framework regularly requires optimized transport coordinations. Whereas visit, little conveyances (frequently alluded to as “drain runs”) can increment the number of trips, the capacity to pack loads effectively and move parts straightforwardly to the line, or maybe than to a centralized stockroom for double-handling, can lead to:

- Lower Holding Costs: Less capital tied up in inventory.

- Ideal Asset Utilization: Guaranteeing crude materials and labor are utilized accurately when request is proven.

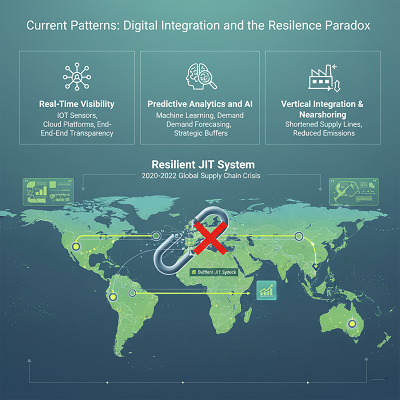

Current Patterns: Computerized Integration and the Strength Paradox

The 2020-2022 worldwide supply chain emergency uncovered JIT’s most basic defenselessness: a need of flexibility. The framework, optimized for effectiveness, frequently needed the stock buffers fundamental to climate major, erratic disturbances like a widespread, geopolitical struggle, or normal disaster.

This delicacy has not driven to the deserting of JIT, but or maybe its advancement. The current slant is to coordinated JIT standards with progressed computerized instruments to make a more “Versatile JIT” or “Keen Incline” system.

The Part of Technology

- Real-Time Perceivability: IoT sensors, cloud stages, and progressed supply chain administration (SCM) computer program give end-to-end straightforwardness, permitting companies to see a potential disturbance some time recently it stops production.

- Prescient Analytics and AI: Machine learning calculations presently handle endless sums of data—from climate designs to social media trends—to make hyper-accurate request estimates. This permits for a more versatile JIT show, which can construct little, key buffers as it were when a high-risk occasion is predicted.

- Vertical Integration and Nearshoring/Reshoring: To relieve the chance of long, complex worldwide supply chains, numerous companies are shortening their supply lines. Bringing generation closer to domestic (nearshoring) specifically bolsters a more dependable JIT demonstrate by decreasing transportation separate, taken a toll, and related emissions.

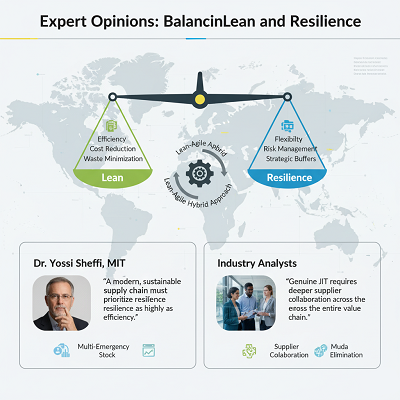

Expert Suppositions: Adjusting Incline and Resilience

Supply chain specialists concur that a immaculate, resolute JIT framework is a obligation in today’s unstable world. The agreement is moving toward a “Lean-Agile Half breed” approach.

Dr. Yossi Sheffi, Executive of the MIT Center for Transportation and Coordinations, has frequently pointed out the perils of single-minded center on moo fetched. His work proposes that a present day, feasible supply chain must prioritize flexibility as profoundly as effectiveness. This implies deliberately presenting redundancy—like multi-sourcing, or holding an crisis stock of a few basic parts—rather than working at supreme zero-inventory.

Industry investigators emphasize that for JIT to genuinely be maintainable, it must be all encompassing. “Pushing stock upstream to your provider doesn’t dispose of squander; it fair moves it,” notes one driving SCM expert. Genuine JIT for maintainability requires more profound provider collaboration where accomplices embrace comparable incline, waste-reduction strategies, successfully disposing of Muda over the whole esteem chain.

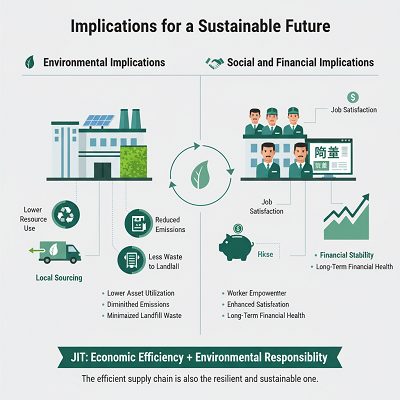

Implications for a Maintainable Future

The extreme suggestion of a fruitful JIT-to-Sustainable show is a principal move in how the economy makes value.

Environmental Implications

JIT, through its center principle of squander lessening, is a capable driver for assembly corporate natural targets. It pushes companies to scrutinize each handle, which constantly leads to lower asset utilization, diminished emanations from less warehousing, and less squander going to landfills. When combined with innovations that optimize transport coordinations and advance neighborhood sourcing, JIT gets to be a basic system for a low-carbon, resource-efficient economy.

Social and Financial Implications

The accentuation on quality control and ceaseless change (Kaizen) inside JIT frameworks can moreover have positive social impacts.

- Specialist Strengthening: JIT frameworks require a exceedingly gifted, cross-trained workforce to recognize and unravel issues on the line. This can lead to expanded work fulfillment and superior labor practices.

- Budgetary Supportability: By killing costs related with squander, holding stock, and out of date quality, JIT essentially progresses the foot line, subsequently guaranteeing the long-term monetary maintainability of the endeavor. This budgetary wellbeing is what eventually supports a company’s capacity to contribute in more costly, but more economical, hones down the line.

In conclusion, Just-in-Time is more than fair a cost-cutting degree; it is a reasoning inherently connected to the standards of a economical future. By constraining businesses to kill squander, it adjusts financial effectiveness with environmental duty. The present day challenge lies in coordination computerized strength to guarantee this incline machine can withstand a stun, demonstrating that the most effective supply chain can moreover be the most solid and most ecologically responsible.