[Dateline: Worldwide Biotechnology Centers] In a critical move pointed at evacuating basic bottlenecks in progressed treatment fabricating, Cell X Innovations and BioLamina have reported a collaboration to upgrade the standardization and reproducibility of initiated pluripotent stem cell (iPSC)-based therapeutics. This organization coordinating two unmistakable however complementary technologies—advanced mechanization and high-quality, characterized organic reagents—to build up a more steady and solid pathway from research facility inquire about to clinical-grade product.

Background and Chronicled Setting: The iPSC Guarantee and Its Shifted Reality

The field of regenerative pharmaceutical, especially that utilizing iPSCs, speaks to one of the most energizing wildernesses in biotechnology. Since the point of interest revelation of iPSCs by Shinya Yamanaka in 2006, these cells—which can be reconstructed from grown-up substantial cells (like skin or blood) into a pluripotent state, permitting them to separate into essentially any cell type—have held the guarantee of “off-the-shelf” or patient-specific cell substitution treatments for conditions extending from Parkinson’s and diabetes to heart failure.

However, deciphering this potential into clinical reality has been reliably hampered by a basic challenge: inconstancy. Truly, iPSC culture and separation depended on complex, ill-defined lattices (like Matrigel, a tumor-derived extricate) and exceedingly manual, operator-dependent forms. This driven to critical batch-to-batch irregularity, making it troublesome to scale generation, guarantee item quality, and fulfill the exacting administrative necessities for Great Fabricating Hone (GMP).

The require for characterized, xeno-free (animal-origin-free) reagents and robotized, exact fabricating stages has gotten to be the central topic in the iPSC fabricating segment. This setting sets the arrange for the key arrangement between Cell X and BioLamina.

The Current Drift: Wedding Science and Automation

The collaboration straightforwardly addresses the industry’s drive toward prescient consistency and scalability.

BioLamina brings its Biolaminin® reagents—defined, full-length, human recombinant laminin isoforms. Laminins are key components of the local cellular microenvironment (the specialty or extracellular lattice) and are pivotal for the survival, development, and useful separation of pluripotent stem cells. By giving a chemically characterized and naturally important substrate, Biolaminin replaces the inconstancy of conventional culture matrices.

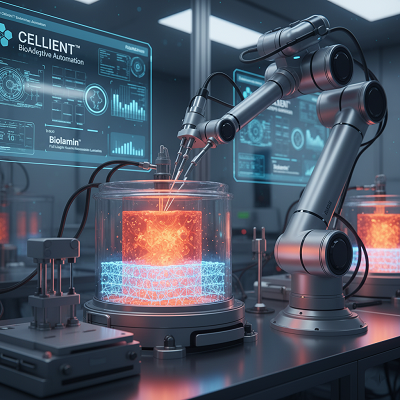

Cell X Advances contributes its Celligent™ stage, a novel combination of mechanical autonomy, imaging, and counterfeit insights (AI). This stage is outlined to robotize the exceedingly complex and iterative forms of cell culture, counting passaging, media changes, and determination, with tall accuracy and negligible human intercession. Urgently, the framework employments AI-driven ‘BioAdaptive Automation™’ to react to the natural prompts of the cells themselves, encourage decreasing operator-dependent errors.

The center objective of the organization is the integration of these two innovations: consistently joining BioLamina’s high-quality reagents into the computerized, high-throughput workflows of the Celligent stage. This is a demonstrate for the future of progressed treatment fabricating: a completely characterized natural framework controlled by a profoundly reliable, robotized process.

Expert Suppositions on the Implications

Industry investigators and specialists see this collaboration as a critical step forward, noticing its center on the regulatory-critical angles of the cell treatment pipeline.

“The organization between a characterized framework master and an mechanization pioneer is a characteristic, nearly inescapable advancement for iPSC fabricating,” says Dr. Elena Rodriguez, a expert specializing in cell and quality treatment fabricating scale-up. “Controllers are requesting strong information on Basic Prepare Parameters (CPPs) and Basic Quality Properties (CQAs). By combining a characterized reagent, which controls the natural input, with an mechanized stage, which controls the procedural input, the inconstancy is minimized, and the information created is gigantically more effective for administrative submissions.”

Another point of positive thinking is the center on “full-length rises to full-function” that BioLamina champions. Klaus Langhoff-Roos, CEO of BioLamina, famous in the collaboration declaration, “Joining forces with Cell X Innovations empowers us to exhibit how full-length breaks even with full-function. This, when combined with progressed mechanization stages, can drive unsurprising consistency and adaptability for iPSC-based fabricating.” This is a coordinate gesture to the industry understanding that truncated or unclear extracellular network components can lead to imperfect or conflicting cell differentiation—a challenge the combined innovation points to eliminate.

Implications: From Lab Seat to Bedside

The victory of this and comparative standardization endeavors carries significant suggestions for the future of progressed therapeutics:

- Quickened Clinical Interpretation: By minimizing fabricating inconstancy and producing vigorous, high-quality information, the combined stage guarantees to quicken the often-slow and expensive move from preclinical advancement to clinical trials and inevitable commercialization. This might altogether decrease the time patients hold up for life-changing therapies.

- Expanded Reproducibility for Worldwide Markets: Standardized, mechanized forms are less demanding to exchange between distinctive fabricating locales all inclusive. This consistency is crucial for multi-center clinical trials and for building up a worldwide supply chain for allogeneic (off-the-shelf) iPSC-derived products.

- Improved Security and Viability: The utilize of characterized, GMP-grade reagents and forms decreases the chance of defilement and guarantees the generation of a homogeneous, high-purity last cell item. This is a basic figure for administrative offices like the FDA and EMA, who prioritize persistent safety.

- Taken a toll Lessening and Versatility: Robotization is the key to scaling cell treatment generation from lab-scale to commercial-scale without corresponding increments in fetched and labor. By streamlining workflows and progressing yields through reliable culture conditions, the collaboration points to make iPSC-based treatments more financially reasonable for huge understanding populations.

The Cell X Advances and BioLamina collaboration is not essentially a commerce assention; it is a coordinate reaction to the most squeezing challenge confronting the iPSC helpful community. By giving an coordinates, approved arrangement that combines characterized science with cleverly robotization, the two companies are making a difference to type in the authoritative outline for fabricating the another era of regenerative medicines.