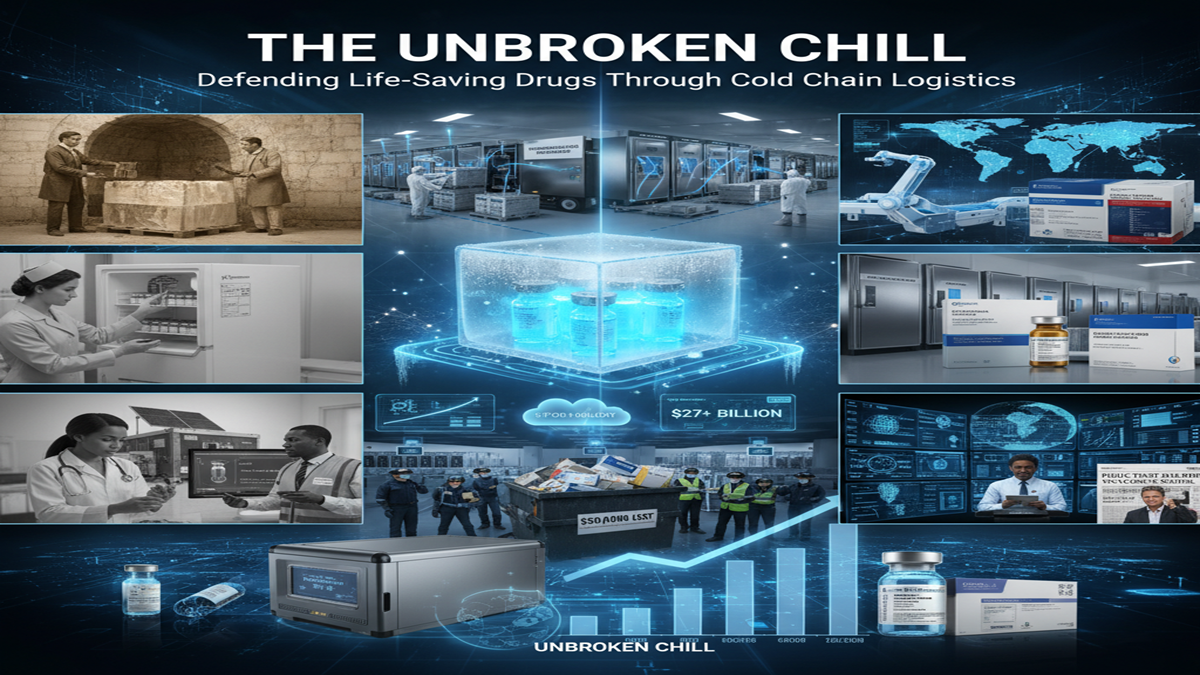

The travel of a life-saving medicate, from a sterile lab to a patient’s arm, is a quiet race against time and temperature. In the complicated world of pharmaceuticals, the cold chain is the immovable gatekeeper, a specialized, temperature-controlled supply chain that is presently more pivotal than ever. As cutting edge medication progressively depends on complex, temperature-sensitive biologics, antibodies, and cell treatments, the astuteness of this cold chain is fundamental, holding the line between viable treatment and exorbitant, life-threatening failure.

Background & Authentic Setting: From Ice Houses to IoT

The concept of keeping up a cold environment for perishable products is antiquated, dating back to ice houses. In any case, the application of this coordinations show to pharmaceuticals is a moderately advanced necessity.

A Century of Cool: The Cold Chain’s Evolution

While the common cold chain developed in the nourishment industry from the late 1700s, with advancements like the refrigerated boxcar in the mid-19th century and Frederick Jones’s innovation of the convenient air-cooling unit for trucks in the 1930s, the pharmaceutical sector’s center on it honed later.

- Mid-20th Century: The cold chain for therapeutic supplies picked up footing in the 1950s, especially with the rise of immunizations and blood items. These early biologics required straightforward refrigeration, regularly between 2∘C and 8∘C (36∘F to 46∘F).

- 1990s and Past: The rise of complex biologic drugs like affront and monoclonal antibodies, which are exceedingly helpless to debasement from warm or solidifying, cemented the cold chain as a need, not a luxury.

- The Administrative Basic: Administrative bodies like the U.S. Nourishment and Sedate Organization (FDA) and the European Medications Office (EMA) set up Great Dispersion Hones (GDP), making thorough, worldwide benchmarks for the capacity and transport of therapeutic products.

The COVID-19 Catalyst

The single most noteworthy later driver for cold chain advancement was the COVID-19 widespread. The arrangement of mRNA antibodies, which required ultracold temperatures (a few as moo as −80∘C), constrained an uncommon and quick worldwide scaling of ultracold chain coordinations . This challenge acted as a worldwide push test, quickening mechanical appropriation and infrastructural advancement that presently benefits the whole pharmaceutical landscape.

Current Patterns: The Computerized Insurgency in Temperature Control

Today’s pharmaceutical cold chain is a profoundly modern, technology-driven environment planned to dispose of “temperature excursions”—deviations exterior the worthy run that can render a sedate dormant or toxic.

1. The Rise of Ultracold and Cryogenic Logistics

The pipeline for progressed treatments, counting cell and quality treatments (CGTs), is booming. These treatments frequently require cryogenic capacity, now and then underneath −150∘C, kept up by specialized holders utilizing fluid nitrogen. This specialized coordinations section is one of the fastest-growing and most in fact challenging.

2. Keen Checking and Real-Time Visibility

The period of basic logbooks is over. Web of Things (IoT) sensors, implanted in bundling and capacity units, give real-time information logging of temperature, mugginess, and area. This is coupled with:

- Prescient Analytics: AI and machine learning are utilized to analyze course information, climate estimates, and chronicled execution to proactively distinguish potential disturbances and recommend possibility plans.

- Blockchain Innovation: Whereas still developing, blockchain offers a tamper-proof advanced record for all taking care of and temperature information, upgrading auditability and administrative compliance all through the worldwide supply chain.

3. Progressed Bundling Solutions

Innovations in inactive and dynamic bundling frameworks are making transport more secure and more sustainable:

- Stage Alter Materials (PCMs): These materials keep up a particular temperature for an expanded period by retaining or discharging vitality as they move between stages (e.g., strong to fluid). They offer a more steady and frequently lighter elective to conventional ice or gel packs.

- Progressed Separator: Vacuum-Insulated Boards (VIPs) and high-performance froths give predominant warm security, expanding the length a shipment can keep up its temperature range.

- Re-usable Holders: A center on maintainability is driving the appropriation of high-performance, approved, and re-usable holders, diminishing squander and long-term costs.

Expert Conclusions: Center on Information, Preparing, and Infrastructure

Industry pioneers and supply chain specialists reliably stretch a few key regions for future cold chain robustness:

On Foundation and Worldwide Reach:

“The dissimilarity in cold chain foundation between created and creating countries remains a basic challenge,” notes one coordinations expert. “You can have the most progressed bundling, but a control blackout at a travel center in a inaccessible region can still invalidate the shipment. Venture in localized, solid cold capacity and reinforcement control is non-negotiable for genuine worldwide wellbeing value.”

On Administrative Compliance and Training:

A pharmaceutical compliance officer emphasizes, “GDP is the bedrock. Each single individual who touches the product—from the producer to the last-mile conveyance driver—must be thoroughly prepared on legitimate dealing with conventions and trip relief. The most noteworthy mechanical checking framework is useless if the human component comes up short to act on a basic alert.”

On Innovation and Investment:

“The move from being basically reactionary—responding to a temperature outing after it happens—to being proactively prescient is the major change,” clarifies a bio-pharma coordinations VP. “We’re not fair moving boxes; we’re overseeing a mountain of information to guarantee the product’s quality budget is never surpassed. This requires noteworthy, progressing speculation in IoT, AI, and cloud-based information platforms.”

Implications: The Tall Stakes of an Unbroken Chain

The need of an productive, uncompromised cold chain carries significant suggestions for the pharmaceutical industry, open wellbeing, and the worldwide economy.

Consequences of Failure

The stakes are gigantic. A break in the cold chain—an startling temperature spike or drop—can have serious consequences:

- Misfortune of Item Viability and Security: Numerous biologics, counting immunizations and affront, lose their strength if their atomic structure is harmed by temperature change. This can render a treatment totally ineffectual, driving to destitute persistent results, and, in the most exceedingly bad cases, can cause unfavorable side impacts or passing. The World Wellbeing Organization (WHO) gauges that about 50% of immunizations are squandered universally each year due to dishonorable temperature management.

- Monetary Catastrophe: The worldwide fetched of pharmaceutical cold chain disappointments, enveloping item misfortune, transfer, and reviews, is evaluated to be in the tens of billions of dollars yearly. A single high-value shipment of a cell treatment might be worth millions, making the misfortune of indeed one holder an financial blow.

- Administrative Sanctions and Reputational Harm: Disappointments lead to seriously investigation from administrative bodies and potential fines. Moreover, open believe in life-saving solutions, particularly antibodies, is exceedingly touchy to news of item spoilage.

Looking Ahead: Advertise Development and Resilience

The future of pharmaceutical R&D is intensely weighted toward temperature-sensitive items. As worldwide request for claim to fame solutions, personalized pharmaceutical, and biosimilars increments, the cold chain coordinations advertise is anticipated for critical development, likely coming to well over $27 billion in the coming years.

The basic is clear: the unbroken chill is the strict help for a developing parcel of cutting edge medication. For pharmaceutical companies, coordinations suppliers, and governments alike, acing this complex, high-stakes supply chain is not just a competitive advantage—it is a crucial duty to guarantee that basic, life-saving treatments reach each understanding securely, dependably, and effectively.