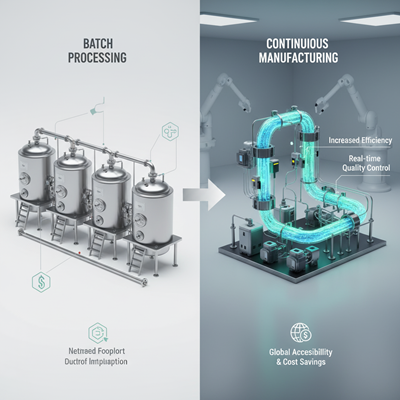

For decades, the biopharmaceutical industry has depended on a conventional clump fabricating model—a prepare of discrete, consecutive steps frequently compared to making a feast one formula at a time. Each organize, from cell development to decontamination, is a partitioned, contained occasion, with materials held in tanks and exchanged between stations. But a unused worldview is clearing the industry, promising to on a very basic level reshape how life-saving medications are made. Nonstop fabricating, a strategy long utilized in businesses from nourishment to petrochemicals, is presently balanced to revolutionize bioprocessing, advertising uncommon picks up in effectiveness, taken a toll investment funds, and worldwide accessibility.

From Clump to Stream: The Authentic Context

The roots of bioprocessing follow back to antiquated aging hones for making bread, brew, and wine. In any case, the present day biopharmaceutical period, which started with the disclosure and large-scale generation of penicillin in the 20th century, was built on the group show. This framework, whereas solid and well-understood, is inalienably restricted. It’s time-consuming, requires huge offices, and is inclined to changeability between clusters. Each stop between steps makes a potential bottleneck, and the require for visit cleaning and sterilization includes to both fetched and downtime.

The concept of ceaseless fabricating has been around for decades, but its application in the exceedingly directed and complex world of biopharmaceuticals confronted noteworthy obstacles. The complex nature of natural atoms and the strict quality control necessities made the move from a “stop-and-go” to a “continuous” prepare appear overwhelming. Be that as it may, progressions in innovation, especially in robotization, real-time checking, and single-use frameworks, have made persistent bioprocessing a reality.

A Modern Time of Productivity and Fetched Savings

At its center, ceaseless fabricating includes a steady, continuous stream of materials from crude fixings to wrapped up item. This principal move offers a cascade of benefits:

- Increased Efficiency: By killing the downtime related with group changeovers, offices can create a higher volume of item in a littler sum of time. A few gauges propose a 10-fold increment in efficiency compared to conventional strategies. This is especially impactful for high-demand drugs.

- Reduced Impression: Nonstop forms are exceedingly heightens, meaning they can accomplish the same or more prominent yield with essentially littler gear and a littler physical impression. This deciphers to diminished capital and operational expenses.

- Lower Costs: The combination of higher efficiency, littler offices, and diminished labor needs specifically interprets to a lower fetched of merchandise sold per unit. This is a basic calculate in making costly biologic drugs more affordable.

- Enhanced Quality Control: The persistent, steady-state environment of a nonstop prepare permits for reliable working conditions and real-time checking. Progressed sensors and Handle Explanatory Innovation (PAT) give a consistent stream of information, permitting for prompt rectifications and guaranteeing item quality remains inside indicated parameters. This diminishes batch-to-batch inconstancy and the chance of defects.

Current Patterns and Master Opinions

The move toward ceaseless bioprocessing is picking up energy, driven by a juncture of mechanical progressions and a steady administrative environment.

- Integrated Frameworks and Robotization: The objective is to make a completely associated, end-to-end prepare. This requires advanced mechanization and advanced integration to oversee the persistent stream and information collection. The utilize of manufactured insights and machine learning is too on the rise, empowering prescient upkeep and assist handle optimization.

- Single-Use Innovations: The appropriation of single-use frameworks, such as expendable sacks, tubing, and channels, is a key enabler. They dispense with the require for broad cleaning and sterilization, decreasing turnaround times and the chance of cross-contamination.

- Regulatory Bolster: Administrative bodies, counting the U.S. Nourishment and Sedate Organization (FDA), have effectively empowered the selection of ceaseless fabricating. They recognize its potential to progress item quality and supply chain vigor. The FDA’s Developing Innovation Program has given a pathway for companies to talk about and resolve potential specialized and administrative issues some time recently a formal accommodation, clearing the way for quicker approvals.

According to Dr. Lawrence Yu, previous Agent Chief of the FDA’s Office of Pharmaceutical Quality, the group prepare is “wasteful and inclined to absconds.” He notes that the FDA is “exceptionally interested in supporting the development of ceaseless fabricating” to move forward medication quality and address potential medicate deficiencies. Dr. Ding Ming, a bad habit president at the U.S. Pharmacopeia (USP), emphasizes that “quality benchmarks are a basic require for [persistent fabricating] progression and multiplication,” and the USP is working to standardize terms and materials to encourage this move globally.

Global Suggestions: A Way to More noteworthy Accessibility

The suggestions of a far reaching move to nonstop bioprocessing amplify distant past the plant floor. The effectiveness and fetched investment funds might have a significant affect on worldwide health.

- Tending to Supply Chain Vulnerabilities: The littler, more spry nature of persistent offices implies they can be built and conveyed more effectively. This permits for more prominent expansion of fabricating destinations, diminishing dependence on a few large-scale offices and making the worldwide supply chain more strong to disturbances like pandemics or common disasters.

- Increasing Get to to Solutions: By bringing down the taken a toll of merchandise, nonstop fabricating can offer assistance make life-saving biologic drugs, which are frequently restrictively costly, more open to patients in creating countries. The innovation permits for a more decentralized and disseminated fabricating demonstrate, bringing generation closer to the populaces that require it most.

- Accelerating Time-to-Market: The capacity to move from advancement to commercial generation more rapidly, with less scale-up dangers, implies modern treatments can reach patients quicker. This is particularly pivotal for developing areas like cell and quality treatments, where the request for fast, adaptable fabricating is high.

While the move to ceaseless fabricating presents challenges, counting the tall starting speculation and the require for a gifted workforce, the overpowering benefits are driving the industry forward. It’s a worldview move that guarantees not fair to make bioprocessing more productive, but to make a substantial contrast in the lives of patients worldwide.