In the exceedingly directed world of sterile medicate fabricating, an unforeseen hardware disappointment is not fair a calculated migraine; it’s a disastrous chance. It debilitates the keenness of the clump, compromises understanding security, and can result in millions of dollars in misplaced item and remediation costs. Nowadays, a modern era of advanced tools—Artificial Insights (AI) and Machine Learning (ML)—is changing the industry’s responsive approach to upkeep into a proactive, data-driven technique, basically giving producers a gem ball for the cleanroom.

Background: The Tall Stakes of Sterile Production

Sterile fabricating, which incorporates the generation of injectables, ophthalmics, and other delicate treatments, works beneath the strictest administrative oversight, administered by Great Fabricating Hone (GMP) rules. The littlest deviation—a inconspicuous temperature float in a lyophilizer (freeze-dryer), a worn bearing in a filling line isolator, or an discuss handler engine battling in the HVAC system—can present defilement or compromise sedate stability.

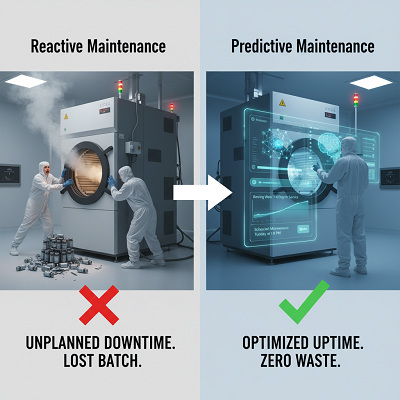

Historically, upkeep in this division depended on two essential methods:

- Responsive Support: Settling hardware after it has fizzled, driving to spontaneous downtime, high-cost crisis repairs, and the potential misfortune of an whole item batch.

- Preventive Support (PM): Performing upkeep on a settled plan (e.g., each six months), notwithstanding of the real condition of the gear. This approach is frequently wasteful, coming about in superfluous downtime, squandered labor, and the untimely substitution of costly, however still utilitarian, parts.

The advanced worldview of Prescient Upkeep (PdM) points to strike the ideal adjust: interceding at the exact minute some time recently a disappointment occurs.

Historical Setting: From Manual Logs to Shrewd Sensors

The way to AI-driven PdM is established in the mechanical advancement toward more prominent robotization and information collection.

In the late 20th century, condition-based checking (CBM) started supplanting settled PM plans. This included utilizing essential sensors to screen gear for edge breaches—for case, alarming staff if a motor’s vibration or temperature surpassed a set restrain. Be that as it may, these frameworks were oversimplified, regularly creating untrue cautions or lost unpretentious, raising problems.

The genuine breakthrough came with Industry 4.0 and the intersection of three technologies:

- The Mechanical Web of Things (IIoT): The expansion of low-cost, high-fidelity sensors (for vibration, acoustics, control draw, warm imaging, etc.) that nourish Enormous Information in real-time.

- Cloud and Edge Computing: The capacity to store and prepare gigantic datasets right away, either locally at the “edge” or remotely in the cloud.

- Machine Learning: The improvement of modern algorithms—such as neural systems and profound learning—capable of analyzing complex, high-dimensional sensor information to recognize designs characteristic of approaching disappointment. Not at all like straightforward edge cautions, AI models learn the special “signature” of ordinary gear operation and can identify miniature deviations a long time some time recently a human, or a essential CBM framework, could.

Current Patterns: The AI-Driven Cleanroom

Today, sterile producers are quickly moving to implant this insights into their most basic resources. Key patterns characterize this shift:

Digital Twins for Handle Validation

Companies are building Advanced Twins—virtual copies of their whole generation lines or basic resources like bioreactors and aseptic filling frameworks. These twins ingest real-time information from their physical partners, permitting engineers to reenact hardware behavior beneath different conditions, test upkeep methodologies, and indeed demonstrate the affect of component debasement on the sterility envelope—all without gambling a real-world batch.

Edge Computing and Administrative Compliance

Due to strict information security rules (like GDPR) and the require for low-latency reactions, there is a drift toward conveying AI models at the edge—closer to the hardware on the plant floor. This guarantees real-time responsiveness and keeps touchy operational information inside secure, neighborhood purview, which helps in administrative compliance with benchmarks like 21 CFR Portion 11.

Focus on Basic Assets

AI is being particularly prepared to screen and anticipate disappointments in high-value, high-risk gear fundamental to sterility:

- Aseptic Filling Lines: Observing seal astuteness, pump wear, and automated alignment.

- Lyophilizers (Freeze-Dryers): Following compressor execution and vacuum integrity.

- HVAC Frameworks: Analyzing channel proficiency, fan engine wellbeing, and discuss weight differentials, which are non-negotiable for keeping up cleanroom classifications.

Expert Suppositions: Believe, Straightforwardness, and Validation

While the eagerness for AI is tall, industry pioneers and controllers emphasize a cautious, consider approach.

Dr. Eleanor Vance, a expert specializing in Pharma 4.0 approval, notes that the greatest jump is not the innovation itself, but the believe and straightforwardness required by administrative bodies. “The FDA and EMA won’t essentially acknowledge a ‘black box’ telling them a machine is fine,” she states. “The industry must grasp Reasonable AI (XAI), giving review trails that clearly verbalize why the calculation anticipated a disappointment, connecting the information signature (e.g., a particular consonant in the vibration information) to a known, physics-based disappointment mode. This approval pathway is crucial.”

Another key supposition spins around workforce preparation. Mr. David Chen, a VP of Operations for a major biologics producer, recommends that PdM is not almost supplanting support groups but upskilling them. “We’re moving their part from being wrench-turners to information mediators,” says Chen. “They require to get it what the AI is telling them so they can act on the prescription—and, maybe more imperatively, know when to overrule an incorrect forecast based on their a long time of on-the-floor experience.”

Implications: The Future of Pharmaceutical Reliability

The broad selection of AI-driven prescient upkeep will have significant suggestions over the sterile fabricating esteem chain:

| Implication | Description |

| Increased Persistent Security & Quality Assurance | By anticipating disastrous gear disappointment, the hazard of defilement and compromised item is definitely diminished, guaranteeing tall and reliable medicate quality. |

| Significant Taken a toll Reduction | Estimates recommend PdM can diminish startling office downtime by 5–15% and cut in general support costs by 10–20% by disposing of pointless PM, lessening crisis labor, and avoiding costly clump losses. |

| Enhanced Operational Effectiveness (OEE) | Equipment life expectancy is expanded, and upkeep is planned absolutely amid existing arranged downtime, maximizing throughput and generally gear viability (OEE). |

| The Move to Prescriptive Maintenance | AI will advance from anticipating when a disappointment will happen to endorsing the best course of activity (e.g., “supplant bearing A with portion number 123 in precisely 14 days amid the Tuesday night downtime”), possibly indeed robotizing the parts requesting process. |

| Regulatory System Evolution | Regulatory bodies will be constrained to create clearer rules and guidelines for the approval and reviewing of AI-powered frameworks, assist quickening the industry’s computerized maturity. |

In an industry where certainty is foremost, AI and ML are not fair support devices; they are getting to be fundamental components of a vigorous, compliant, and eventually more solid supply chain for life-saving medications. The days of basically holding up for a machine to break are blurring, supplanted by a modern, cleverly expectation of the future.