A fundamental crossing point of security and sterility is characterizing the taking after time of sedate era. In the high-stakes world of pharmaceuticals, where capable compounds and preeminent sterility are non-negotiable, the customizable “Toxic-Sterile Charging Isolator for Arranging Vessel” is creating as a pivotal, tailor-made course of action, promising exceptional levels of thing cleverness and director assurance

Background and Chronicled Setting

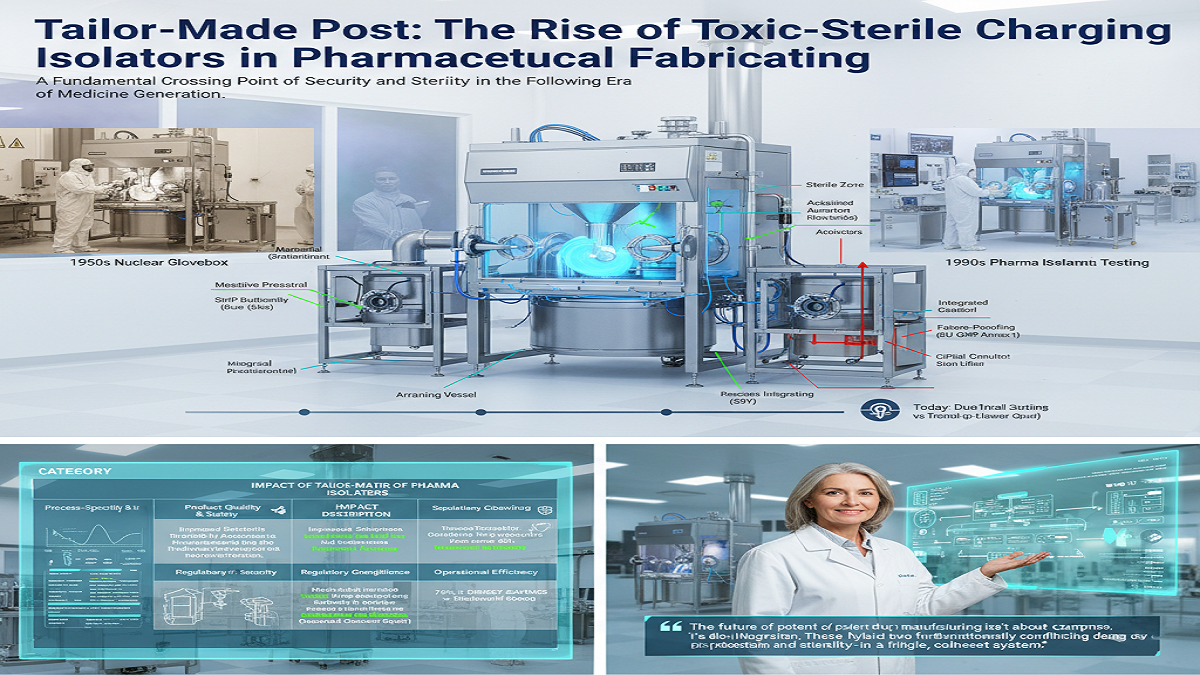

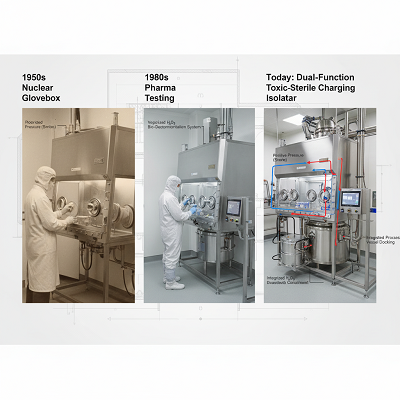

The concept of an isolator—a settled, boundary system—is not unused, with its roots taking after back to glovebox advancement made in the nuclear industry in the 1950s. The pharmaceutical division gotten this development in the early 1980s, at to begin with for applications like sterility testing. These early isolators given an fixed closed boundary, allowing directors to control materials by implies of glove ports while keeping up either a positive (aseptic/sterile) or negative (containment/toxic) inward weight.

However, the fast increase in the era of significantly effective energetic pharmaceutical fixings (HPAPIs), such as those utilized in oncology and next-generation medications, shown a one of a kind and complex challenge. Various progressed drugs require the taking care of of materials that are at the same time:

- Toxic/Potent: Requiring high-level control to secure the director and the environment (e.g., OEB 5 compounds).

- Sterile/Aseptic: Requiring a microbe-free environment to expect thing debasement (e.g., Audit A conditions).

Conventional solutions—like separated clean rooms or committed isolators for as it were one function—were regularly over the top, inefficient, and made a risk of cross-contamination in the midst of texture trade. This dual-requirement drove the change of the Toxic-Sterile Charging Isolator.

The Dual-Function Advancement

A Toxic-Sterile Charging Isolator for a arranging vessel is a progressed, hermetically settled walled in range sketched out especially for the get ready of safely showing energetic fixings (powders or liquids) into a mixing or reaction vessel.

Key Highlights:

Bimodal Weight Control: This is the system’s center progression. The isolator works with a positive weight organization in the midst of the sterile charging organize to secure the thing from the exterior environment. In any case, it can reliably switch to a negative weight organization in the midst of shapes like cleaning-in-place (CIP) or washing-in-place (WIP), or in the midst of high-risk control operations, consequently securing the director from noxious buildups.

- Coordinates Cleaning: The system joins a bio-decontamination system, frequently utilizing Vaporized Hydrogen Peroxide (VHP), to sterilize the working chamber and the texture trade air proof chamber, ensuring a slightest Sterility Affirmation Level (SAL) is met.

- Prepare Integration: The isolator is habitually custom-designed to interface particularly with the arranging vessel, utilizing specialized affiliations like a portion butterfly valve (SBV) and cutting edge docking systems. This affiliation is planned to keep up both control and sterility without interferometer with the vessel’s inward systems, such as stack cells utilized for exact weighing.

- Ergonomics and Robotization: Show day plans consolidate highlights like stainless steel carts or arranges drum lifters to safely manage the introduction of overpowering sacks of texture, reducing the chance of director harm.

Current Designs: The Tailor-Made Basic

The see term’s center on “Tailor made courses of action for your needs” highlights the winning current incline: customization and integration.

- Process-Specific Arrange: Pharmaceutical companies are moving truant from off-the-shelf equipment. Makers by and by offer bespoke isolators built to arrange the adjust estimations, stream necessities, and plan steps of a facility’s existing arranging vessel, ensuring most extraordinary efficiency and compliance.

- Progressed Mechanization and Mechanical innovation: To minimize human intervention—the single most critical source of contamination—isolators are dynamically joining mechanical systems. This incline is particularly clear in small-batch and high-value zones like Cell and Quality Treatment (CGT) manufacturing, where precision and quick changeover are significant.

- Digitalization and Checking: Progressed systems are totally digitalized, with interconnected control systems that screen, record, and control parameters like weight differential, temperature, mugginess, and H2O2 concentration in real-time. This level of data is fundamental for regulatory compliance and audit trails.

- Maintainable Operation: Isolators, in common, are more judicious to work than routine large-scale cleanrooms, which require critical imperativeness for talk about changes. The capacity to put an isolator in a lower-grade cleanroom (e.g., Survey C or D) offers vital capital and operational brought investment funds.

Expert Suppositions and Suggestions

Experts in aseptic dealing with and control planning see the rise of tailor-made toxic-sterile isolators as a fundamental step in pharmaceutical fabricating.

Dr. Eleanor Voss, a brilliant in control development, popular in a afterward industry gathering: “The future of effective sedate manufacturing isn’t nearly compromise; it’s around integration. These hybrid isolators suit two genuinely clashing demands—protection and sterility—in a single, obvious system. The move to custom courses of action recognizes that no two creating shapes are absolutely alike, ensuring that control is an on a very basic level parcel of the get ready, not an add-on.

Recommendations for the Industry:

| Category | Affect of Tailor-Made Toxic-Sterile Isolators |

| Product Quality and Security | Improved Sterility Affirmation: The closed system and mechanized VHP cycle offer a transcendent level of sterility compared to schedule cleanrooms, unquestionably reducing the chance of microbial defilement. |

| Operator Security | Greatest Confirmation: The capacity to switch to negative weight in the midst of high-risk steps gives a solid defense against chairman presentation to HPAPIs, gathering inflexible word related introduction limits (OELs). |

| Regulatory Compliance | Future-Proofing: These systems alter immaculately with overhauled around the world rules, such as the EU GMP Include 1 rectifications, which emphasize the utilize of closed, boundary systems to keep up aseptic conditions. |

| Operational Effectiveness | Expanded Throughput & Versatility: Customization grants for perfect workflow, minimizing texture managing with steps and diminishing bunch changeover time. Their lower operational brought, compared to broad classified circumstances, makes strides the in common creating economy. |

The progression from direct control boxes to significantly customized, bimodal toxic-sterile charging isolators talks to a advancement of pharmaceutical building. It ensures that as the sedate pipeline continues to center on continuously capable and complex iotas, the system is in put to give secure, sterile, and sensible drugs to patients worldwide.