The pharmaceutical industry, a section characterized by its intensive quality rules and essential mission, is encountering a critical alter. The ensure of computerization, fueled by mechanical independence, Fake Experiences (AI), and advanced data analytics, is no longer a cutting edge concept but a rapidly spreading out reality adjusted to reexamine how arrangements are found, made, and manufactured. This move is driven by twin weights: the increasing around the world ask for drugs and the industry’s endless require for more essential viability, consistency, and compliance.

Background and Bona fide Setting

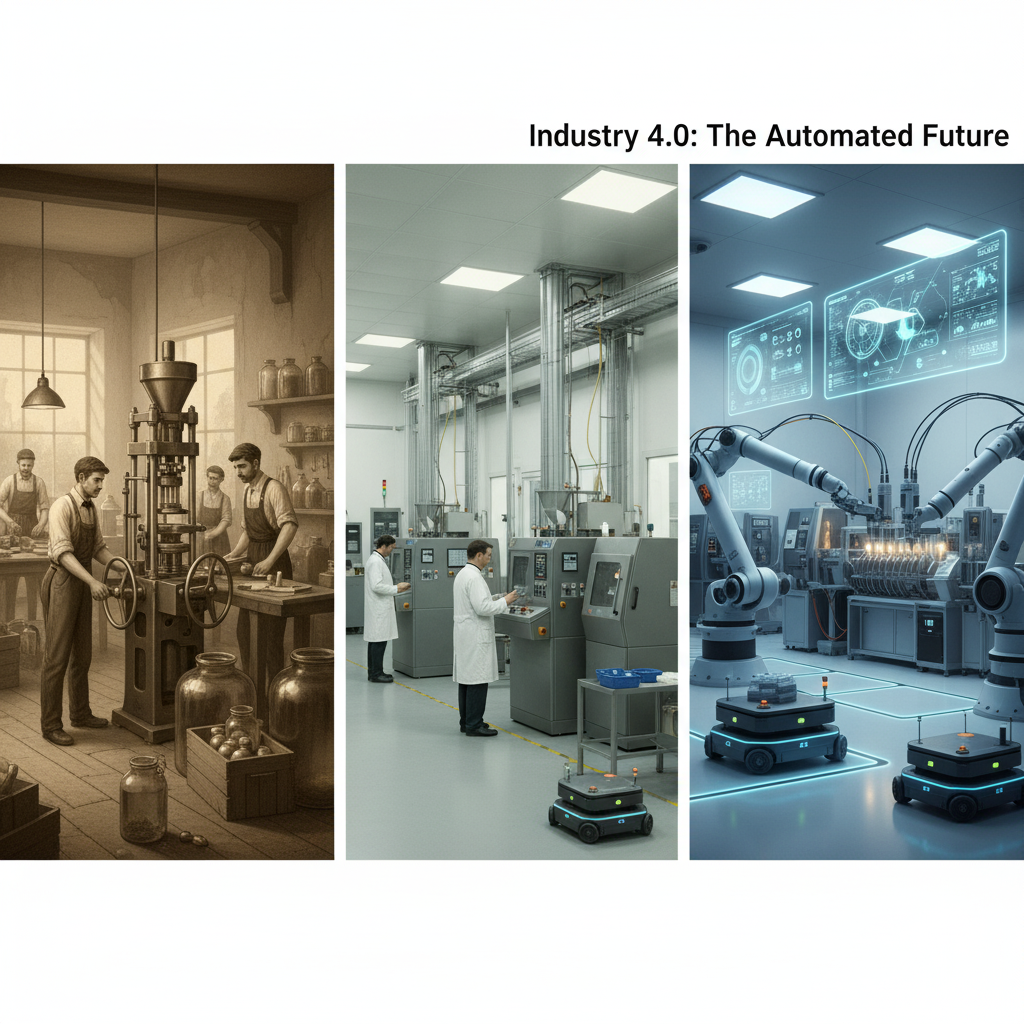

The travel toward mechanization in sedate era begun decades back, progressing from essential mechanization to complex, interconnected frameworks.

Historically, pharmaceutical manufacturing was a labor-intensive, batch-based handle. The basic steps toward mechanization risen in the 19th and early 20th centuries with the introduction of mechanical contraptions for assignments like tablet compression and capsule filling. These machines definitely extended era speed and consistency over manual labor.

A more basic bounce happened in the mid-20th century. The enhancement of electronic controls in device, taken after by the introduction of Computer-Aided Manufacturing (CAM) systems in the 1980s, allowed for more streamlined, quick era of complex drugs like anti-microbials. This period laid the establishment for display day plan control and observing.

Today, the industry is getting a handle on Industry 4.0 propels, joining sensors, the Web of Things (IoT), and competent computational devices. The COVID-19 broad served as a essential accelerant, outlining the squeezing require for versatile, high-speed, and adaptable manufacturing capabilities to meet remarkable around the world request.

Current Designs: The Columns of the Robotized Future

Modern mechanization is intensifying far off past direct physical substitution of human labor. It incorporates an integration of progressed progresses over the entire pharmaceutical regard chain:

1. Mechanical innovation and Advanced Apparatus

- Exactness Creating: Mechanical arms by and by perform high-precision, repetitive assignments like vial filling, bundling, and serialization with unparalleled precision.

- Sterile Circumstances: Computerization in cleanroom circumstances inside and out minimizes the danger of human-introduced contamination, a urgent calculate in sterile sedate generation.

- Independent Convenient Robots (AMRs): These robots transport materials, tests, and wrapped up things between workstations, supplanting manual cart-pushing and updating plant floor coordinations.

2. Fake Bits of knowledge (AI) and Machine Learning (ML)

- Handle Optimization: AI calculations analyze unending datasets in real-time to anticipate equip disillusionments (prescient back), optimize plan parameters, and modify era effectively, driving to higher yields and diminished squander.

- Quality Control (QC): Machine vision systems and ML models are supplanting time-consuming manual evaluation, recognizing smaller than expected absconds at tall speed and ensuring thing consistency.

- Quickened Revelation: AI is as of presently revolutionizing R&D by screening millions of compounds and recognizing promising calm candidates, profoundly shortening the time it takes to move from concept to clinical trial.

3. Ceaseless Manufacturing (CM)

Traditionally, drugs are made in discrete bunches, a time-consuming plan that requires a full end and system cleaning between clusters. Ceaseless Manufacturing livelihoods computerized, arranges systems to run era uninterruptedly. This move, unequivocally reinforced by controllers like the U.S. FDA, offers:

- Quicker era cycles and diminished downtime.

- More firmly handle control with real-time quality affirmation (known as Plan Informative Advancement or PAT).

- Littler office impressions and lower operational costs.

Expert Suppositions and Suggestions

Experts to a extraordinary degree agree that computerization is basic for the future of pharmaceuticals, not reasonable as a cost-cutting degree but as a require for quality and speed.

- “Mechanization is not reasonable nearly supplanting people; it’s around slaughtering changeability and embeddings quality into the center of the get ready. In a coordinated industry, that’s the extraordinary competitive advantage.”

- A common go without among industry specialists.

Key Benefits and Suggestions

Area Affect of Mechanization

Quality & Compliance Near-zero human botch; real-time data logging for come full circle audit trails; ensures adherence to Awesome Creating Sharpens (GMP).

Efficiency & Speed 24/7 operation; diminished cycle times; faster time-to-market, particularly fundamental in the midst of prosperity emergencies.

Cost Decrease Lower labor costs in the long run; diminished waste/rejected bunches; optimized essentialness and resource utilization.

Personalized Pharmaceutical Empowers the calm era of small-batch, customized medicines based on diligent genetic qualities, which is unfathomable with customary bunch handling.

Workforce Security Expels human laborers from risky circumstances counting solid or hurtful chemicals.

Challenges and The Road Ahead

Despite the overwhelming drive, a totally computerized, “lights-out” steady fabricating plant faces vital obstacles:

1. Tall Beginning Speculation

The noteworthy capital utilize required for advanced mechanical independence, AI system, and office redesign is a major boundary, especially for more diminutive and medium-sized endeavors (SMEs).

2. Regulatory Approval

Introducing cutting edge computerized shapes requires wide, costly, and time-consuming authoritative endorsement to illustrate that the system keeps up or makes strides cure quality and efficacy—a preservationist and basic get ready in a field overseeing with determined security.

3. Data System and Computerized Development

Many pharmaceutical companies still work with a separated data scene. To utilize AI and mechanization reasonably, they must to start with set up incredible, secure, and arranges data systems—a challenge known as the “progressed advancement gap.”

4. Workforce Availability

Automation changes the nature of work, requiring a move from manual directors to exceedingly skilled parts centered on system upkeep, data science, and get ready endorsement. The industry faces a lack of specialists with this blend of building, IT, and pharmaceutical ability.

5. Complex Biologics

While computerization surpasses desires in small-molecule calm era, the creating of complex biologics (e.g., immunizations, cell and quality medicines) habitually incorporates exceedingly sensitive, living systems that are more troublesome to computerize and control, in show disdain toward of the truth that this is rapidly changing.

In conclusion, mechanization is not fair a change; it is an formative fundamental for the pharmaceutical division. It ensures a future of dependably higher quality, more sensible, and rapidly open medicines, but its full realization turns on bridging the hole in capital, authoritative deftness, and workforce capacities. The mechanical medicate store is coming, and it will on a exceptionally essential level modify the nature of calm era for the advancement of around the world health.